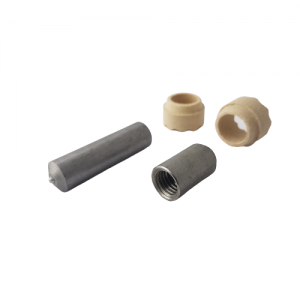

Drawn Arc Weld Standoff (Boss)

Drawn arc stud welding process uses current from a welding rectifier, regulated in terms of power and duration, to produce a high quality ‘stud weld’ with 1 to 3mm penetration depth. Typically used in safety critical applications and for larger diameter fasteners. The flux ball in the tip of the standoff and the use of ceramic ferrules aid the welding process.

Standoffs, sometimes known as Bosses, provide an internal thread for bolting into.

STUD MATERIAL OPTIONS: STEEL SELF FINISH , A2 STAINLESS STEEL , A4 STAINLESS STEEL

| DRAWN ARC PROCESS WELD STANDOFFS - ISO13918 | ||||

|---|---|---|---|---|

| Thread Size | Standoff Lengths | Standoff Diameter | Weld Fillet Dia (approx) | Weld Fillet Height (approx) |

| M5 | 15, 20, 25, 30, 35, 40, 45, 50, 60, 70, 80, 90, 100 | 10 | 13 | 4.0 |

| M6 | 15, 20, 25, 30, 35, 40, 45, 50, 55, 60, 70, 80, 90, 100 | 10 | 13 | 4.0 |

| M8 | 20, 25, 30, 35, 40, 45, 50, 55, 60, 70, 80, 90, 100 | 14.6 | 18.5 | 5.8 |

| M10 | 20, 25, 30, 35, 40, 45, 50, 55, 60, 70, 80, 90, 100 | 14.6 | 18.5 | 5.8 |

| M12 | 25, 30, 35, 40, 45, 50, 55, 60, 70, 80, 90, 100 | 18.3 | 23.2 | 7.0 |

| M16 | 40, 45, 50, 55, 60, 70, 80, 90, 100 | 22 | 28 | 10.0 |

Dimensions in mm. Unit of sale = 100 pcs